Which Motor is Used in CNC Machines? Find Out Here

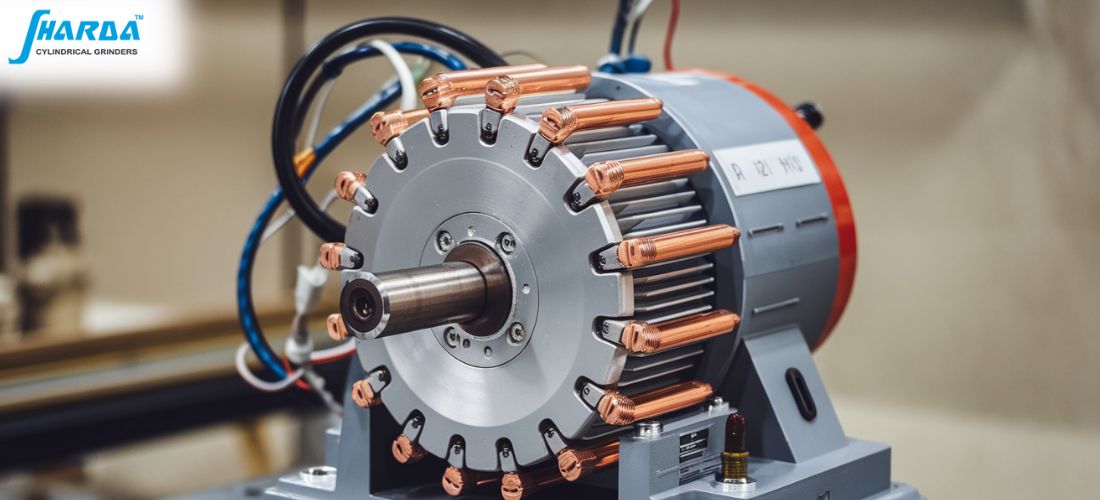

CNC machines have become very popular within the manufacturing industry because of their accuracy, operation efficiency, and automation. Behind every CNC machine lies one central component: the motor.

If you want to discover Which Motor is Used in CNC Machines, this blog is enough to answer your queries. Moreover, we will emphasize its significance in operations carried out by a Universal Cylindrical Grinding Machine, one of the most common CNC machines in industrial settings.

Types of Motors Employed in CNC Machines

Among the many motors that are used in CNC machines, two are commonly mentioned.

Stepper Motors

- Step motors find their place in CNC machines because of precise movement.

- They usually operate in discrete steps, which makes them fit for any high-accuracy task, whether it be engraving, milling, or drilling.

- To get the best performance from stepper motors, it is suggested to always match them with a controller that manages the motor and guarantees micrometric precision while machining.

Servo Motors

- Servo motors form another category of the most popular motors in CNC machines.

- Their working is very much in contrast to that of stepper motors, in that servo motors use a closed-loop system that corrects themselves in case of a positional error.

- This effectively makes them very reliable for long operations that require consistency, like those performed by the Universal Cylindrical Grinding Machine.

Why Are These Motors Preferred in CNC Machines?

Both eager stepper and servo motors each have advantages that make them relevant to CNC.

- 1. Precision: No matter if you are caringly carving and shaping two designs or regularly making equal parts. This motor ensures precisely fine work.

- 2. Dependability: These motors are capable of doing the work repetitively and effectively a hallmark for any CNC machining.

- 3. Versatility: Because of their functionalities and abilities, stepper and servo motors are flexible in small desktop CNC routers to even industrialized Universal Cylindrical Grinding Machines.

Applications of CNC Machines and Their Motors

Many types of CNC machines have many applications in various industries. Within such machines, the choice of motor directly affects performance, such as in processes like CNC cylindrical grinding. What is a CNC Cylindrical Grinding? It’s a precision machining process used to shape cylindrical parts.

- 1. Surface Finish: A good quality motor ensures smooth, fine, and even grinding across various pieces.

- 2. Speed of Operation: Modern motors, such as servo motors, run faster without losing position accuracy.

- 3. Durability:This kind of motor is very sturdy, hence excellent for industrial applications.

Factors to Consider When Choosing a Motor for CNC Machines

To properly understand which motor types to use in CNC machines, one must examine certain parameters defining their efficiency and suitability as a matter of concern here:

- 1. Torque and Speed: Torque is required to cut tough materials; speed helps in executing the job on time. Servo motors are better capable of providing both.

- 2. Power Consumption: In heavy Industry, this is important due to the consideration of an energy-efficient machine. Unlike stepper motors, their power consumption is lesser.

- 3. Noise levels:For those applications that should not be loud, the choice would go to stepper motors, with their low noise operation being a motivation.

- 4. Cost:Stepper motors are cheaper and, therefore, suitable for smaller operations. However, with the precision of some applications involving the Universal Cylindrical Grinding Machine, it is justified to invest more in a servo motor.

Advancements in Motor Technology

With new advances and changes, CNC machines and their motors are also innovated. These improvements focus mainly on efficiency, precision, and durability. For instance:

- 1. Hybrid Stepper Motors: A combination of the advantages of both stepper and servo motors gives it better precision and lesser power consumption.

- 2. Direct Drive Motors: Used in only some advanced CNC machines meant to eliminate transmission elements to ensure optimization and also require less maintenance.

- 3. Integrated Motors:Inbuilt encoders and controllers, hence simplifying installation and enhancing performance monitoring.

CNC Machines in India: A Growing Market

The number of CNC machines in India is burgeoning. With this, manufacturing in India is moving very fast, and industries, ranging from automotive to defense, heavily depend on CNC machines powered by high-performance motors. Universal cylindrical grinding machines, for example, have the power to produce high-precision components that are used in critical applications.

By introducing new machines with better motors, Indian manufacturers are taking up CNC directly to meet the global standards of quality that let us meet international competitiveness.

Conclusion

So, which motor is used in a CNC machine? Stepper motors and servo motors play vital roles; however, their selection will depend on the applications and performance required. These motors deliver unmatched precision and efficiency for everything from helmet works to cylindrical surface grinding in the Universal CNC grinding machine.

In conclusion, be it a hobby while exploring CNC technology or a profession associated with manufacturing, knowing which motor is adopted in the CNC machine can help make wise choices. As represented in the applications involving Universal Cylindrical Grinding Machines, the choice of a motor can greatly influence a machines performance and outcomes.

Also Read: What Is a CNC Machine Used for in Manufacturing?