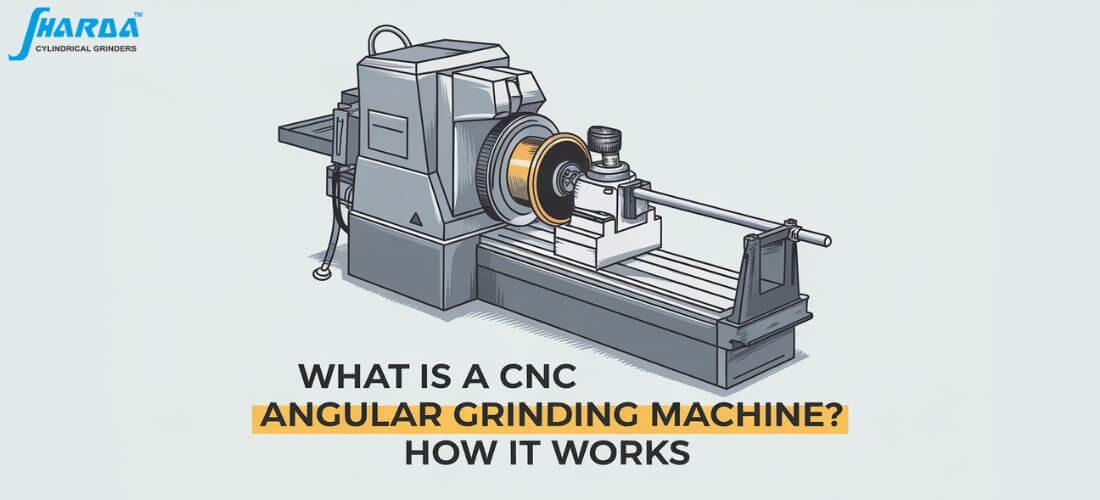

What is a CNC Angular Grinding Machine? How It Works

In the realm of precision planning, the CNC Angular Grinding Machine stands as a testament to technological advancement. This sophisticated machine tool ought to perform precise angular grinding operations on a large number of workpieces, from easy to complex calculations. By consolidating the force of Computer Numerical Control (CNC) innovation with advanced grinding frameworks, medium CNC Angular Grinding machine offer unmatched accuracy, viability, and repeatability.

Understanding What is CNC Angular Grinding Machine

Before bobbing into the intricacies of CNC Angular Grinding Machines, making heads or tails of the fundamental standards of angular grinding is essential. Angular grinding incorporates eliminating material from a workpiece utilizing a rotating abrasive wheel that is situated at a particular angle. This blog will briefly explain what is Duty Angular CNC machine.

How to be a CNC Machine Operator?

Traditional grinding machines, which were manually operated, anticipated that gifted operators ought to achieve precise outcomes. However, with the advent of CNC innovation, grinding machines have gone through a significant transformation. CNC Angular Grinding Machines are furnished with PC-controlled frameworks that can execute complex grinding operations with remarkable precision.

Key Parts of a CNC Angular Grinding Machine

A typical CNC Angular Grinding Machine comprises several key parts:

- 1. Machine Bed: The foundation of the machine, giving stability and determination.

- 2. Workhead: Stands firm on and tractions the workpiece during the grinding framework.

- 3. Grinding Wheelhead: Houses the grinding haggle drive framework.

- 4. CNC Control Framework: The "brain" of the machine, controlling all axes of progress and the grinding framework parameters.

- 5. Coolant Framework: Eliminates heat generated during the grinding framework and flushes away debris.

How a CNC Angular Grinding Machine Capabilities

Part Programming

The initial step incorporates creating a PC program that characterizes the ideal shape and aspects of the workpiece. This program is typically written in a specialized language like G-code.

Workpiece Arrangement

The workpiece is safely clamped onto the workhead, guaranteeing accurate situating and orientation.

Grinding Wheel Determination

The appropriate grinding wheel is picked based on the material to be ground, the ideal surface finish, and the normal material removal rate.

Grinding Interaction

The CNC control framework coordinates the advancement of the work head and grinding wheel head, precisely following the programmed path. The grinding wheel eliminates material from the workpiece, shaping it to the ideal contour.

Finishing Operations

Reliant upon the ideal surface finish, additional finishing operations like polishing or polishing may be performed.

Advantages of CNC Angular Grinding Machines

Precision and Accuracy

CNC machines can achieve unquestionably elevated degrees of precision and accuracy, guaranteeing that the final thing satisfies outrageous quality standards.

Capability

CNC machines can perform complex grinding operations in a fraction of the time anticipated by manual strategies.

Repeatability

CNC machines can consistently convey identical parts, diminishing variability and further creating thing quality.

Adaptability

CNC machines can handle a large number of workpiece materials and calculations, making them versatile tools in manufacturing conditions.

Decreased Labor Expenses

CNC machines can automate many tasks, diminishing the prerequisite for gifted labor and reducing creation costs.

Applications of Medium CNC Angular Grinding Machine

CNC Angular Grinding Machines are broadly utilized in various organizations, including:

- 1. Automotive: Grinding of motor parts, transmission gears, and other precision parts.

- 2. Aerospace: Grinding of turbine blades, blower parts, and other aerospace parts.

- 3. Tool and Fail appallingly Making: Grinding of cutting tools, passes on, and shape.

- 4. Medical Gadget Manufacturing: Grinding of implants, prosthetics, and surgical instruments.

Medium Duty Angular CNC Machine

Medium Duty Angular CNC Machine is a popular decision for predominantly most manufacturing applications. They offer a balance of force, precision, and versatility, making them suitable for a broad variety of grinding tasks. These machines are capable of handling medium-sized workpieces and can beneficially eliminate material at moderate rates.

Future of CNC Angular Grinding

The fate of CNC Angular Grinding is poised for significant advancements, driven by technological innovations and creating industry demands. Coming up next are several critical patterns to watch:

- 1. Advanced Automation: The integration of advanced automation innovations like mechanical frameworks and artificial information will additionally streamline operations and enhance viability.

- 2. Enhanced Machine Learning: Machine learning algorithms can analyze vast amounts of data generated by CNC machines to streamline performance, anticipate maintenance needs, and work on overall adequacy.

- 3. Further created Sensor Innovation: Advanced sensor advances, including high-precision sensors for temperature, vibration, and power, will enable real-time monitoring and control of the grinding framework.

- 4. Additive Manufacturing Integration: The integration of additive manufacturing (3D printing) with CNC grinding can create a variety of manufacturing processes, enabling the advancement of complicated parts with intricate calculations.

- 5. Sustainable Manufacturing: The improvement of energy-capable CNC machines and the utilization of eco-accommodating coolants and lubricants will add to sustainable manufacturing practices.

Conclusion

This blog explains what is CNC Angular Grinding machine and how it has disturbed the field of precision planning. Via automating complex grinding operations and conveying exceptional accuracy and repeatability, these machines have become indispensable tools in present day manufacturing. As innovation keeps on advancing, we can hope to see considerably more sophisticated CNC Angular Grinding Machines that push the boundaries of precision and capability.

Also Read: How to be a CNC Machine Operator: Tips for Beginners