SPM CYLINDRICAL GRINDING MACHINE

The product stands out for its robust construction, precision, and efficiency. Engineered to handle mass and batch production, SPM Cylindrical Grinder Machine Exporter caters to medium and heavy-sized components, making it ideal for various industries requiring high precision and reliability.

SPM Cylindrical Grinder Machine

ECG 800 - 1250 (S.P.M)

Details of our SPM Cylindrical Grinder Machines

The SPM Cylindrical Grinder Machine offers a cost-effective solution with options for straight or angular wheel head configurations, ensuring versatility and efficiency.

Continuously measures the diameter being ground and compares it to pre-set values, ensuring accurate dimensions.

FlaggingDetects the end face position on the workpiece, reducing idle time and ensuring safety.

Dynamic Balancing SystemCompensates for the imbalance of the grinding wheel, improving surface finish and workpiece geometry.

Gap Eliminator / Crash ControlAutomatically detects setup or machining conditions, retracting the grinding wheel rapidly for safety.

Linear Scale for X and Z AxisProvides feedback on actual slide movement like Straight Eco Series CNC Machine gives the CNC system up to the submicron level.

Benefits of SPM Cylindrical Grinder Machine

The SPM Cylindrical Grinder Machine offers numerous benefits:

High Precision: Achieves intricate shapes and exceptional precision.

Reliability: Designed for high reliability and easy maintainability.

Cost-Effective: Provides a cost-effective solution for mass and batch production.

Customization: Offers optional accessories and configurations to meet specific grinding needs.

SPM Cylindrical Grinders Applications

- Automotive Industry

The SPM Cylindrical Grinder Machine is used for grinding precision engine components and gears, ensuring high accuracy and smooth operation of automotive parts. - Aerospace Sector

This machine achieves tight tolerances on critical aerospace parts, contributing to the safety and efficiency of aerospace components. - Medical Field

In the medical field, the SPM Cylindrical Grinder Machine Manufacturer is essential for precision implants and surgical instruments, where accuracy is paramount. - Energy Sector

The machine grinds turbine components for enhanced performance, supporting the energy sector's need for reliable and efficient parts. - General Engineering

Meeting various precision grinding requirements, the CNC cylindrical grinder machines are versatile and essential for general engineering applications.

MACHINE BASE

The machine base is manufactured of one piece close grained graded cast iron. Box type design, heavily reinforced with ribs, provides high rigidity and stability.

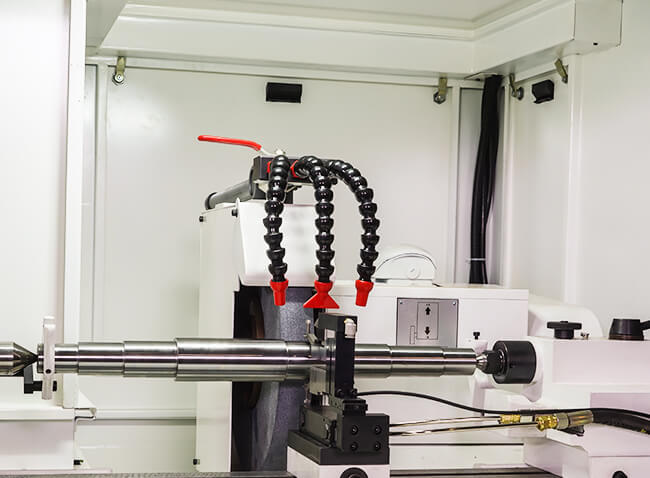

MACHINE GUIDEWAYS

- V & Flat guide ways precisely hand scrapped for Cross (X-Axis) & Table slides (Z-Axis) with turcite coating which gives stick slip free movement

- Excellent vibrations damping and high positioning accuracy, which insures better lubrications and longer life of guide ways.

- The X-Axis can be equipped with linear measuring system, depending upon requirements (Optional).

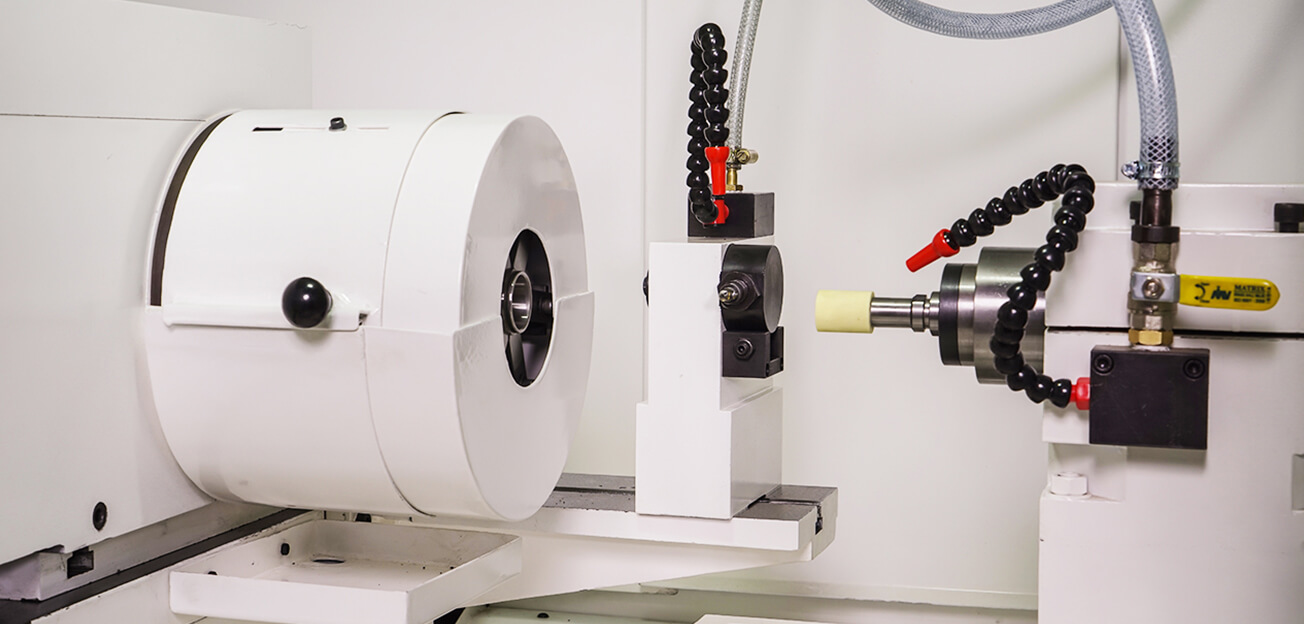

WORK HEAD

- Dead Centres as standard, live cum dead centres as optional

- Easy belt tensioning arrangement.

- Special arrangements provided in front to avoid entry of coolant inside work head.

WHEEL HEAD

- Cartridge type grinding wheel spindle operating at 45 m/s cutting speed & with precision anti friction bearings. Constant Cutting Speed of grinding wheel though variable speed drive (Optional)

- Robust wheel head with anti-friction bearings is maintenance free has good thermal stability.

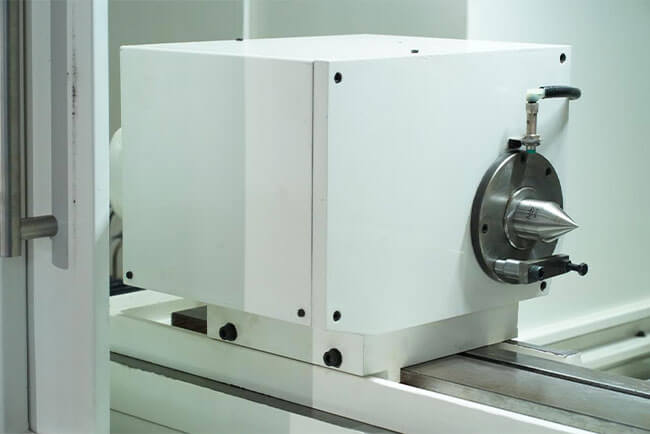

TAIL STOCK

- Rigid design and facility for adjusting Tail stock quill clearance.

- Hydraulic actuation (Optional)

- Micro correction attachment for taper settng +0.030 (Optional)

- Robust design of machine elements with high reliability and easy maintainability.

- The ECG Series is developed for grinding of mass and batch production of medium and heavy size components. This machine offer a cost effetive solution with straight or angular wheel head option.

OPTIONAL ACCESORIES

AUTOMATIC IN-PROCESS GAUGE

IPG automatically and continuously measures the diameter being ground and compares the actual size to pre-set values. Confirming the diameter to the accurate dimension.

FLAGGING

Detects the end face position on work piece, reduces idle time and ensure safety.

DYNAMIC BALANCING SYSTEM

Dynamically compensates the imbalance of grinding wheel. Balancing system improve the surface finish and geometry of the work piece.

GAP ELIMINATOR / CRASH CONTROL

This device will automatically detect the setting up or machining condition occurs, the grinding wheel will rapidly retract for safety.

LINEAR SCALE FOR X AND Z AXIS

Gives actual slide movement feedback to CNC system up to submicron level.

| DISCRIPTION | UNIT | 500 | 800 | 1000 | 1250 | |

| CAPACITY | ||||||

| Swing over Table | mm | 300 | 300 | 300 | 300 | |

| Admit Between Centres | mm | 500 | 800 | 1000 | 1250 | |

| Maximum Grinding Diameter | mm | 200 | 200 | 200 | 200 | |

| Maximum weight of job between centres | kg | 80 | 80 | 80 | 80 | |

| WHEEL SLIDE (X-AXIS) | ||||||

| Guide ways type | V and Flat (LM Guide)* | V and Flat (LM Guide)* | V and Flat (LM Guide)* | V and Flat (LM Guide)* | ||

| Rapid feed rate | m/min | 10 | 10 | 10 | 10 | |

| Resolution of X-AXIS | mm | 0.001 | 0.001 | 0.001 | 0.001 | |

| TABLE (Z-AXIS) | ||||||

| Guide ways type | V and Flat | V and Flat | V and Flat | V and Flat | ||

| Swivelling Angle | deg. | 6° to 2° = 8° | 6° to 2° = 8° | 6° to 2° = 8° | 5° to 2° = 7° | |

| Rapid feed rate | m/min | 10 | 10 | 10 | 10 | |

| Resolution of Z-AXIS | mm | 0.001 | 0.001 | 0.001 | 0.001 | |

| WHEEL HEAD | ||||||

| Spindle Design | Cartridge type with Anti friction bearings | |||||

| Grinding wheel Size (OD x W) | mm | 500 x 80 | Surface Speed | m/s | 45 / 60* | 45 / 60* | 45 / 60* | 45 / 60* |

| Motor Power | kW | 5.5 | 5.5 | 5.5 | 5.5 | |

| WORK HEAD | ||||||

| Centre | MT | 5 | 5 | 5 | 5 | |

| Spindle Speed | RPM | 50 – 500 | 50 – 500 | 50 – 500 | 50 – 500 | |

| TAIL STOCK | ||||||

| Centre | MT | 4 | 4 | 4 | 4 | |

| Quill Travel | mm | 40 | 40 | 40 | 40 | |

| Taper Correction (Optional) | mm | 0.040 | 0.040 | 0.040 | 0.040 | |

| CONTROL SYSTEM | FANUC / SIEMENS | |||||

| GENERAL | ||||||

| Operation voltage | Volts | 415 +/- 10 % AC 3 Phase | ||||

| Floor Space (without coolant tank) | mm | 2900 x 1700 | 3500 x 1700 | 3900 x 1700 | 4400 x 1700 | |

| Floor Space (with coolant tank) | mm | 2900 x 2500 | 3500 x 2500 | 3900 x 2500 | 4400 x 2500 | |

This is a versatile and reliable choice for industries requiring high precision and efficiency in their grinding operations. As an SPM Cylindrical Grinder Machine supplier, investing in this machine ensures high-quality, precise grinding for various applications.