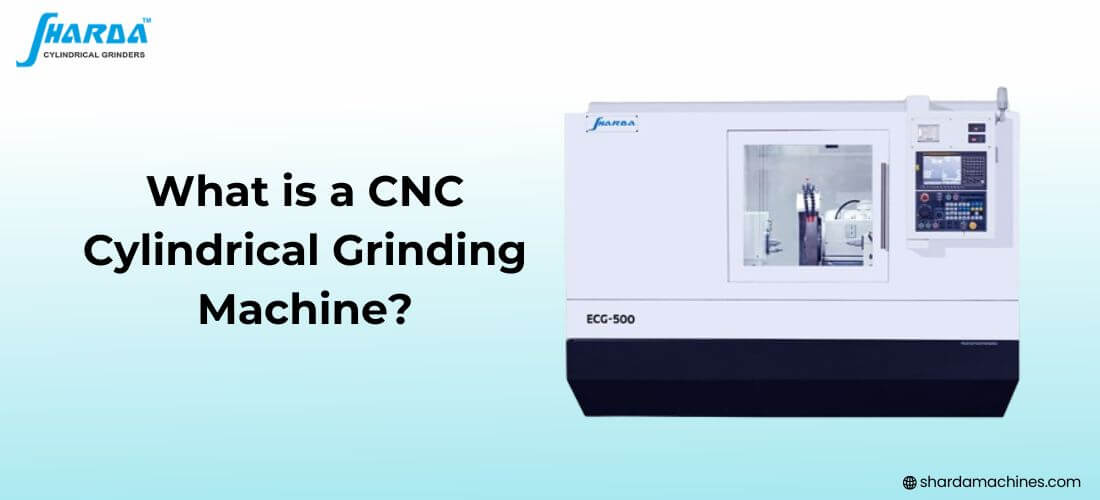

What is a CNC Cylindrical Grinding Machine?

A CNC cylindrical grinding machine is a specialized mechanism for grinding cylindrical surfaces especially. Automotive, aerospace, manufacturing, and toolmaking are just a rare of the sectors that heavily depend on these tools. They are important to the production of finely machined parts with tight tolerations and soft textures. The operation uses, advantages and developments of CNC cylindrical grinding machines will all be covered in this article.

The procedure of grinding cylindrical surfaces is directed as cylindrical grinding. Shafts, rods, and additional cylindrical components that need a high degree of precision and surface quality are treated using this method. Through scraping, the grinding process eliminates material from the workpiece's surface, leaving a precise and delicate finish.

Components of a CNC Cylindrical Grinding Machine

A standard CNC cylindrical grinding machine is constructed up of a few fundamental parts:

The introductory tool for removing material from the workpiece is the grinding wheel. Depending on its usefulness, it arrives in a variety of dimensions, shapes, and materials. It is formed of connected abrasive particles.

- Workpiece: The item that has to be ground is known as the workpiece. It is secured in place by a chuck or different holding mechanism and placed on a revolving spindle.

- Machine Bed: The machine bed operates as the grinding machine's foundation, supporting and stabilizing the other parts. Usually, cast iron or another hard material is used to complete it.

- Headstock & Tailstock: The workpiece is held in place and rotation is delivered by the headstock. For stability during grinding, the workpiece's opposite end is supported by the tailstock.

- Control System: The CNC cylindrical grinding machine's brain is the control system. It is produced by a computer, software, and several detectors and actuators that control how the machine moves and procedures.

- Coolant System: Grinding produces a lot of warmness, which can damage the grinding wheel and the workpiece. The coolant system pushes coolant around to remove warmth and maintain the grinding procedure lubricated.

Working Rule of CNC Cylindrical Grinding Machines

A CNC Cylindrical Grinding Machines methodology in various cycles as notices:

- Planning: The workpiece is mounted on the machine and the crushing wheel is obliged by the administrator. The right estimations, resiliences, and crushing stages are modified into the organization framework.

- Grinding process: The workpiece turns gradually while the crushing wheel pivots rapidly. The workpiece is moved by the crushing wheel, which eliminates material from its surface. The workpiece and the crushing wheel are precisely kept up with the length of speed and development by the administration framework.

- Cooling and Lubrication: To help the crushing haggle workpiece from overheating and to guarantee a smooth crushing strategy, coolant is siphoned.

- Finishing: The crushing system is finished when the expected estimations and surface completion are gained. In the wake of being rescued once again from the machine, the workpiece is quality-assessed.

Utilizations of CNC Cylindrical Grinding Machines

CNC Cylindrical Grinding Machines are used in different venturesome natures and applications on account of their accuracy and adaptability. A couple of regular applications have:

- Automotive Industry: Driving rods, camshafts, and transmission posts are among the high-accuracy machine parts that are delivered utilizing a CNC cylindrical grinding machine. To give the most extreme execution and dauntlessness, these elements expect to keep up with high surface completions and explicit resiliences.

- Aerospace Industry: Turbine shafts, landing gear parts, and tension driven actuators are among the central parts made by CNC cylindrical grinding machines in this area. To ensure steadfastness and affirmation, these parts need to join to extreme quality requirements and versatility.

- Manufacturing Industry: CNC cylindrical grinding machines are used in the collecting industry to convey a broad assortment of exact parts, similar to bearings, gears, and machine tool spindles. These parts are essential for the smooth movement of various hardware and gear.

- Toolmaking Industry: CNC cylindrical grinding machines are utilized to produce high-accuracy cutting devices, like drills, reamers, and end factories. These apparatuses require exact aspects and surface completions to guarantee productive and precise cutting execution.

- Medical Industry: In the clinical business, CNC barrel CNC cylindrical grinding machines are utilized to deliver accurate parts for clinical gadgets, like orthopedic implants, surgical instruments, and dental tools. These parts require high accuracy and surface completion to guarantee legitimate usefulness and biocompatibility.

Advantages of CNC Cylindrical Grinding Machines

CNC Cylindrical Grinding Machines offer a few advantages over traditional grinding machines:

- Precision: CNC Cylindrical Grinding Machines give high degrees of accuracy and precision, ensuring that parts meet tight resistances and determinations.

- Consistency: CNC innovation ensures reliable and repeatable developments, reducing the risk of human errors and working on general quality.

- Effectiveness: CNC cylindrical grinding machines can perform complicated grinding operations rapidly and productively, reducing creation time and costs.

- Flexibility: CNC cylindrical grinding machines can be customized to play out a comprehensive variety of grinding operations, making them suitable for other applications and industries.

- Computerization: CNC cylindrical grinding machines can be coordinated with robotization frameworks, like automatic loaders and transportation, to further expand effectiveness and reduce work expenses.

Conclusion

CNC cylindrical grinding machines are basic machines in present-day production, offering high degrees of precision, consistency, and expertness. They are used in other ventures to produce basic parts with tight resiliences and excellent surface completions. With continuous progress in innovation, CNC cylindrical grinding machines keep on developing, delivering considerably more important capacities and performance. Whether in an automobile, flight, manufacturing, toolmaking, or medical industry, CNC cylindrical grinding machines assume an essential part in creating premium quality, precision-engineered components.